GMP Clinical Manufacturing

High Quality, Efficient, Reliable, Cross-Functional Manufacturing

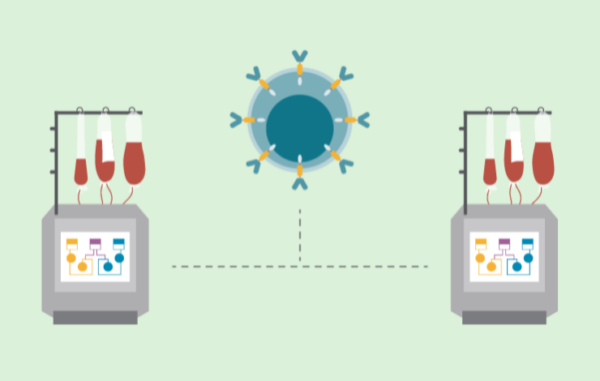

BioCentriq owns and operates facilities that are designed exclusively for cell therapy manufacturing. All sites are fully equipped with standard equipment to manufacture autologous and allogeneic therapies using both open and closed processes. We have the quality systems and procedures in place to manufacture and release drug product. Our facilities provide end to end, in-house GMP capabilities to complement our Process and Analytical Development Laboratories to ensure smooth transfer and cross functional alignment throughout your products lifecycle. Our GMP manufacturing team are experts at producing high quality, drug products. The cross-functional teams consist of qualified aseptic operators who have years of experience in biologic manufacturing and have been trained and onboarded for drug product manufacturing.

Why Choose BioCentriq?

Facility Details and Specifications

All our facilities are less than three years old. We have four manufacturing suites of different sizes and equipment with open and closed processes for both autologous and allogeneic manufacturing.

Our GMP Manufacturing suites are fully validated and registered with the FDA and include the following:

- Building Management Systems (BMS) for control of suite temperature and pressures

- Validated Environmental Monitoring System (EMS) for alarm and trending of suite temperature, humidity and pressurization

- Segregated air handlers supporting each suite

- Two to three BSCs and other standard equipment

- Controlled access

- Material pass-throughs

We have dedicated training space available in our Newark, NJ location. The space can be customized to suit your training requirements. Currently, it includes the following:

- Six BSCs in a mock laboratory environment

- Mock gowning area with benches and mirrors

- Sealers and welders available for use

- Set up and additional equipment can be sourced to suit your needs

- Classroom space with whiteboards and audio-visual support

- Easy access via public transportation and plentiful parking