Manufacturing, Science, and Technologies (MSAT)

From Bench to Bedside With BioCentriq's MSAT Team

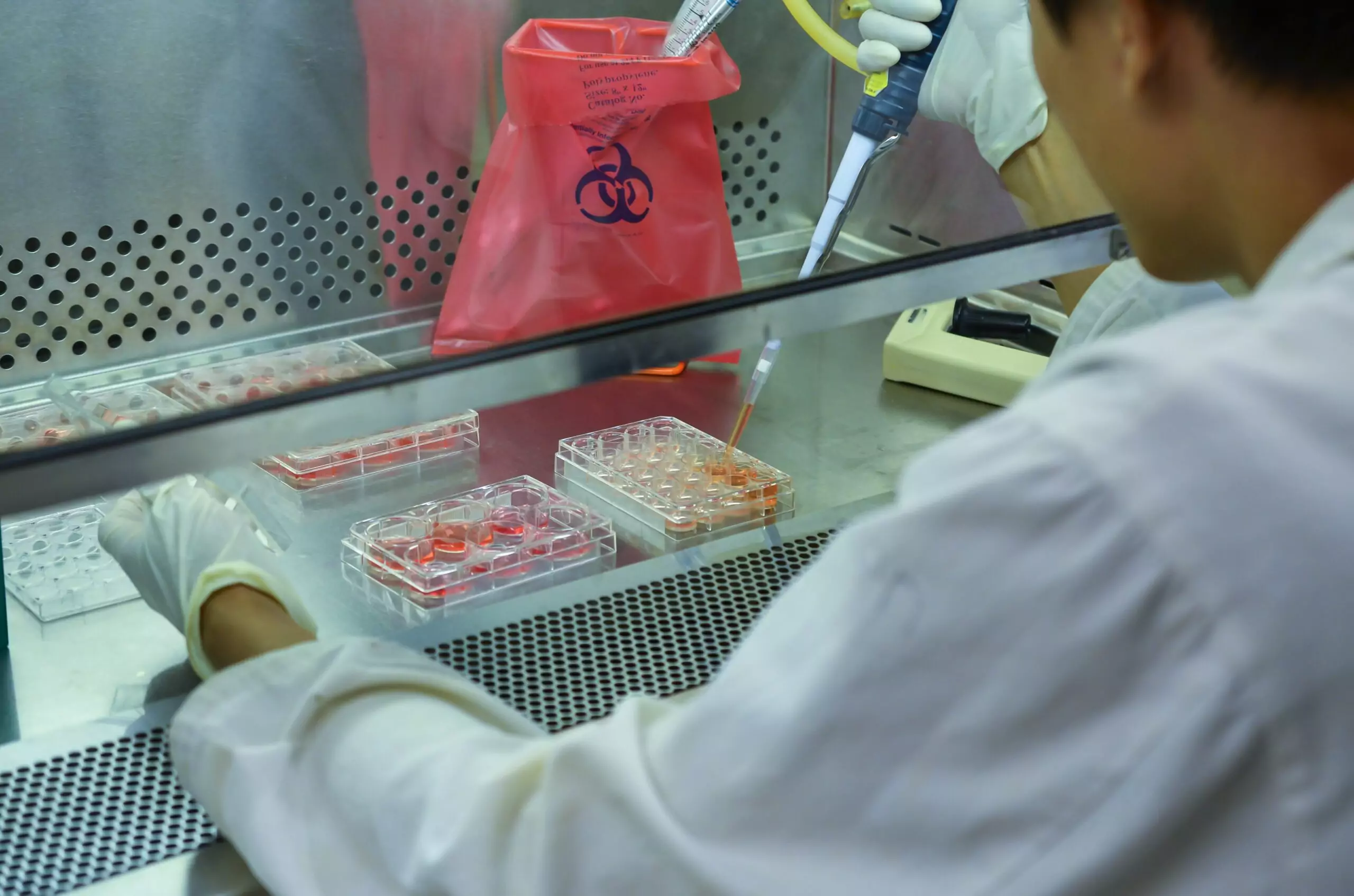

BioCentriq's MSAT team serves as a hands-on liaison between our partners and our own process development and manufacturing teams, working to consistently improve how therapies are advanced from bench to bedside.

Our MSAT team is equipped with the technical know-how and regulatory insights to ensure the successful translation of novel processes into the manufacturing suite. We perform quality assessments as early as possible in the product lifecycle and employ Quality-by-Design principles to determine key attributes and parameters critical to the production of high-quality drug products.

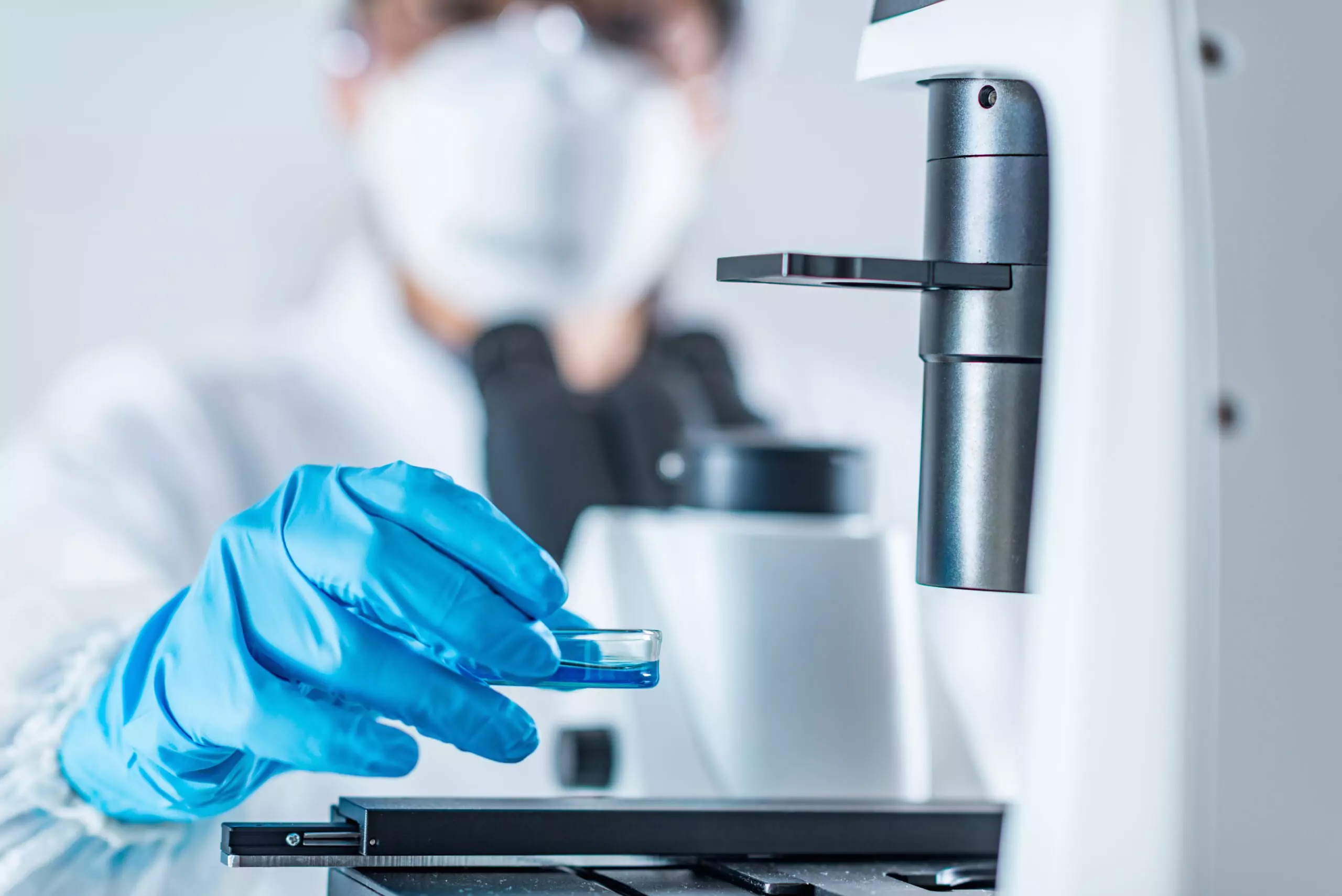

Working closely with our partners, we first help identify the Quality Target Product Profile and Critical Quality Attributes (CQA) for the therapeutic. The MSAT team seeks to define the Critical Process Parameters and Critical Material Attributes and key inputs to the process, all based on the CQAs initially identified.

Our team works closely with biotech companies who have early-stage cell therapy products that are either autologous or allogeneic and rely on a variety of cell lines. Our expertise spans multiple modalities, and our standard approach is designed to ensure successful tech transfer of products in any clinical phase.

The BioCentriq Approach to MSAT

Learn More About MSAT at BioCentriq

Our MSAT team combines diverse expertise that's used to bring your product from bench to scale. Learn more about how we optimize tech transfers and utilize a Quality by Design framework to get your product to clinic.

MSAT Creates a Bridge to Successful Manufacturing

The BioCentriq Team

Combining years of specialized experience and technical expertise, the BioCentriq MSAT team thrives at the intersection of our clients and our process development and manufacturing teams.

They employ an open communication style to help identify issues before they arise, understand the diverse needs of each project, and ensure a smooth process from start to finish.

Get to know the team that will be pivotal in helping take your therapy to market.

Mary Loveras

Melissa Mastro

Senior Engineer, MSAT