Process Analytical Development

Design. Develop. Optimize.

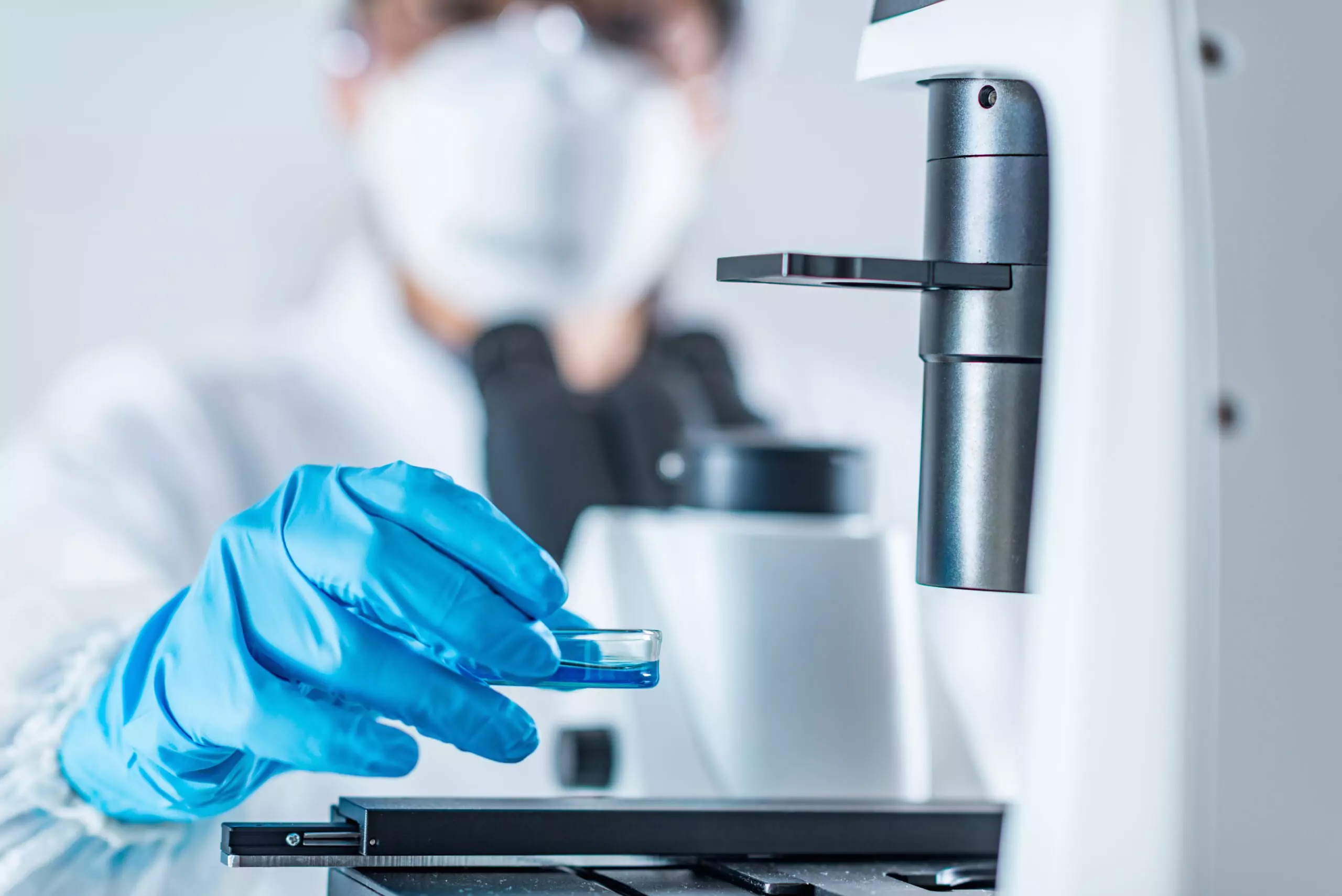

We have established an effective process analytical development team and platform that can be tailored to meet your unique needs. Our job is to help you evolve from your current state to your desired future state.

Our team leverages deep expertise in process and analytical development to establish and scale up processes that achieve optimal yield and cost efficiency based on sound science, engineering, and cGMP design.

We take a team with vast experience across a wide range of technologies and modalities and place them in state-of-the-art facilities with leading edge process technologies with access to partners in MSAT and manufacturing to ensure that the work they do will be GMP ready.

Why BioCentriq for Process Analytical Development?

Engaging MSAT and manufacturing early ensures GMP readiness.

BioCentriq's Approach to Process Analytical Development

We start every process analytical development project with a careful review of all your documentation to date and a feasibility study followed by a detailed gap assessment, and we move on from there based on the unique goals of your program.

After knowledge transfer of the existing process, our team employs a Quality-by-Design product strategy to advance and scale up the process to one that is robust, phase-appropriate, and commercially viable.

Our analytical development team provides comprehensive custom assay development services to ensure effective product and process characterization. We also have pre-established standard assays available to fast-track your method development..

Strategic Process Analytical Development is the Foundation for Successful Clinical Manufacturing

The BioCentriq Team

The scientists, analysts and engineers in our process analytical development group oversee, design, and execute experiments to develop and optimize processes for a variety of products.

They come to us from companies like BMS, Novartis, Merck, Legend Biotech, Pfizer and more.